Counters are used in PLC programming to track and count events or situations, such as the quantity of objects that have gone through a conveyor belt, the frequency with which a certain sensor fires, or the frequency with which a machine completes a cycle. This is made possible by the counter commands used in PLC programming.

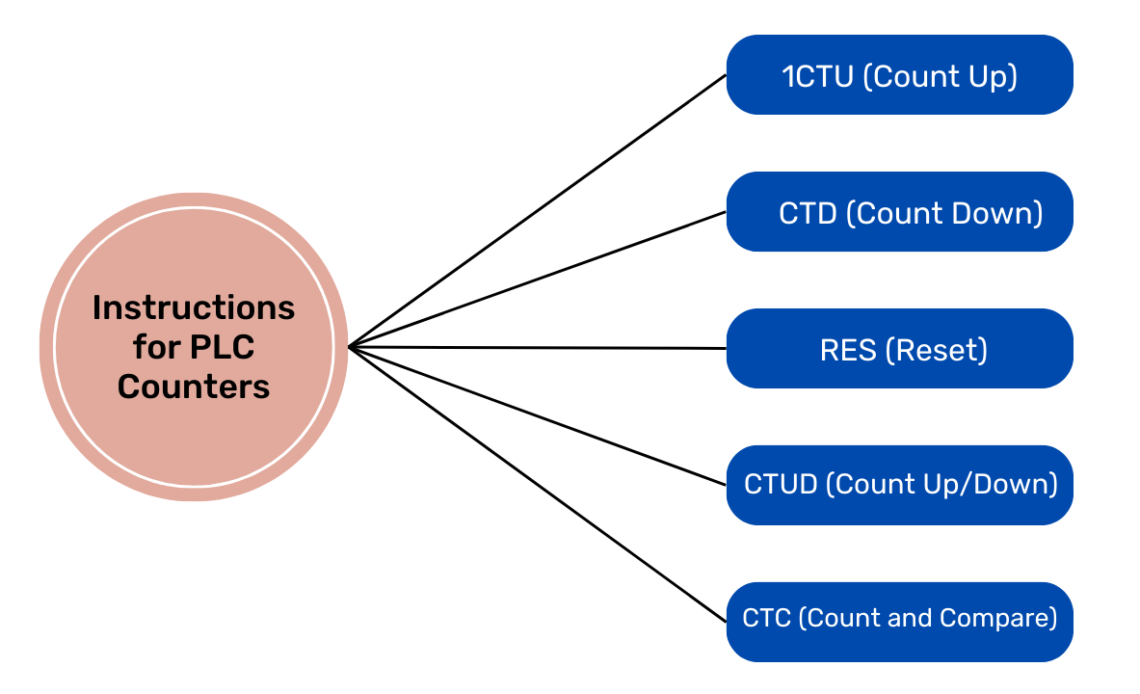

Listed below are some typical PLC Counter instructions:

-

CTU (Count Up):

In PLC programming, the CTU command increments a predefined counter each time a certain trigger event takes place. A programme event or an output may be activated when the counter reaches a certain value. The CTU instruction can be used in structured text, ladder logic, or other programming languages that are supported by the specific Allen Bradley PLC, and the counter value can be kept in a register or memory address.

Applications for the CTU instruction include monitoring the number of times a machine completes a cycle, counting the number of items produced in a given amount of time, and measuring the number of times a product goes through a specific area of a production line.

- Input Condition: You provide a digital input circumstance that will cause the counter to start counting. Any device that emits a signal when the event you wish to count occurs might be connected to this input condition, such a sensor, switch, or other hardware.

- Transition Detection: The up counter watches for a change from a “false” state to a “true” state under the provided input condition. This transition denotes the occurrence of the event you wish to count.

-

CTD (Count Down):

When a certain trigger event happens, the PLC programming instruction CTD counts down a preset counter. A programme event or an output may be activated when the counter hits zero. The CTD command can be used in structured text, ladder logic, or other programming languages that are supported by the specific PLC, and the counter value can be kept in a register or memory address.

Applications for the CTD instruction include keeping track of how much time is left until a specific event, keeping track of how many inventory items are still in a stock room, and keeping track of how much time is left before a machine needs repair.

- Counter Decrement: The counter begins to decrease by a value of 1 when the input condition changes from true to false. If required, you can set the counter to decrease by a different amount.

- Preset Value: You can set the counter’s pre-set value. The amount here indicates how many counts the counter will make before it stops. Once the counter value is zero, the counter can start a certain process or cause an event, such setting off an alarm, or it can trigger a specific action.

-

RES (Reset):

In PLC programming, the RES command resets a specified counter to zero. The RES command can be used in structured text, ladder logic, or other programming languages that are supported by the specific PLC, and the counter value can be kept in a register or memory address.

The RES command can be used for a variety of tasks, such as resetting a counter after a predetermined number of items have been created, resetting a timer after a predetermined amount of time has passed, and resetting a machine’s cycle clock after maintenance.

Check :- Rockwell Automation 1766-L32BXBA MicroLogix 1400 PLC

-

CTUD (Count Up/Down):

The CTU and CTD commands are combined to form the CTUD instruction in PLC programming. Depending on the direction indicated in the programme, it increments or decrements a predetermined counter each time a certain trigger event takes place. A programme event or an output may be activated when the counter reaches a certain value. The CTUD instruction can be used in structured text, ladder logic, or other programming languages that are supported by the specific PLC, and the counter value can be kept in a register or memory address.

The number of times a machine completes a cycle in either direction, the quantity of goods produced and consumed, and the number of times a sensor is activated in both directions are examples of applications for the CTUD instruction.

-

CTC (Count and Compare):

The CTC command in PLC programming compares a selected counter value to a predefined value and, if the counter value matches the predetermined value, activates an output or initiates an event. The CTC command can be used in structured text, ladder logic, or other programming languages that the specific PLC supports, and the counter value can be kept in a register or memory location.

The CTC instruction can be used to trigger a process change after a certain number of products have been produced, activate an alarm after a certain number of machine cycles have been completed, or turn on a warning light after a specific number of sensor triggers.

PLC counter instructions allow programmable logic controllers (PLCs) to keep track of events, processes, and cycles, which is essential for industrial automation. These commands enable control systems to keep an eye on digital signals and carry out counting operations based on certain circumstances. For precise control, coordination, and monitoring of diverse industrial processes, counter instructions are crucial.

We are Asteam Techno Solutions Pvt Ltd: the go-to company for industrial automation products. We make a contribution to the circular economy by providing all industrial automation products for businesses and factories and also providing service work for them. We provide automation solutions with reputed brands including Allen Bradley, Mitsubishi, Phoenix Contact, Siemens, Schneider, Moxa, VIPA and more. Currently our staff members are serve a growing number of national and international customers each day.